ABOUT XIANGXIN

COMPANY PROFILE

COMPANY PROFILE

In 2016, Fujian Xiangxin initiated the independent research and development of a new energy project. After more than two years of in-depth incubation and result accumulation, Fujian Xiangxin New Energy Automotive Parts Manufacturing Co., Ltd. was officially established in April 2018, becoming one of the pioneers in the field of lightweight intelligent manufacturing for new energy vehicles in China. The company is located in the Electromechanical and Pharmaceutical Industrial Park of Fuzhou High-Tech Zone, covering an area of 200 acres, with business spanning lightweight new energy vehicles, new infrastructure ‘aluminum replacing steel’, production and application of recycled resources, and mid-to-high-end civilian fields. The company has more than 1500 employees, including nearly a hundred R&D technical staff, and collaborates with many well-known experts, universities, and research institutes at home and abroad for R&D cooperation.

Since its establishment, the company has closely revolved around national strategies, building on the twenty-year development of Xiangxin Shares, becoming one of the earliest practitioners of aluminum replacing steel technology in the country. Adhering to the values of ‘strengthening the nation through industry, integrity and pragmatism, maintaining righteousness and innovation, and shared growth’, the company strengthens basic research, emphasizes originality, continuously enhances the transformation of R&D achievements in the new energy field, improves industrialization levels, and grows into a main force driving China’s energy transformation towards green and low carbon.

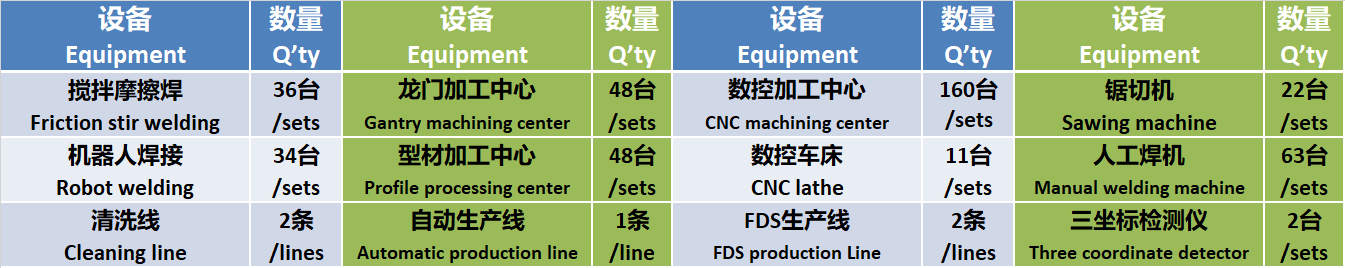

The company is at the forefront of the industry in terms of production capacity and scale for new energy power battery boxes, with the capability to produce 600,000 new energy vehicle power battery boxes annually. The equipment covers the two mainstream processes of FSW (Friction Stir Welding) and FDS (Friction Stir Welding and Diffusion Bonding), and possesses large-scale production equipment and testing, including:

Fujian Xiangxin possesses the production capacity for the entire industrial chain of new energy aluminum alloy battery boxes, module end plates, anti-collision beams, and aluminum alloy energy storage boxes. This includes aluminum alloy melting and casting, mold opening for profile extrusion, aluminum profile extrusion, NC numerical control processing, friction stir welding, robot CMT welding, TIG welding, FDS+ glue application, gantry processing, drawing bending, roll bending, folding bending, sheet metal stamping, cleaning, PVC spraying, insulating powder spraying, polyurethane thermal insulation coating spraying, three-coordinate inspection, air tightness testing, and other processes.

The company’s main clients include major well-known domestic enterprises such as Zhongchuang Xinhang, BYD, CATL (Contemporary Amperex Technology Co., Limited), Funeng Technology, Guoxuan High-Tech, Xingwangda, EVE Energy, Lishen, Futian Automobile, and others.